In the world of fashion and design, technology has continuously pushed boundaries, creating new possibilities for designers, manufacturers, and consumers alike. One of the most exciting developments in recent years is the rise of 3D fabrics. These fabrics are transforming the way clothing is designed, manufactured, and experienced. In this blog post, we will explore the basics of 3D fabrics, their applications in fashion, and why they are poised to play a crucial role in the future of the industry.

What Are 3D Fabrics?

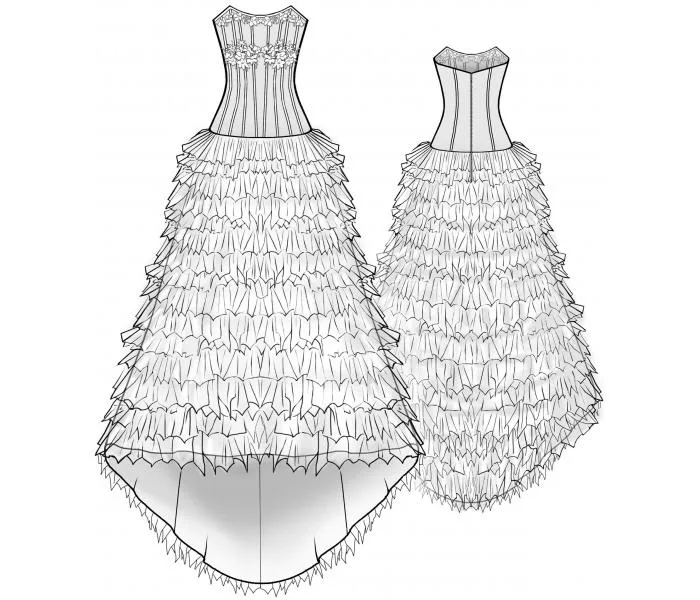

3D fabrics are textiles that have been designed or created using three-dimensional structures, which can be manipulated and customized for various purposes. Unlike traditional 2D fabrics, which are flat and lack depth, 3D fabrics have a more complex structure that can create texture, volume, and form. These fabrics are often created using advanced techniques such as weaving, knitting, or additive manufacturing (3D printing), allowing designers to create intricate patterns and unique surface effects that are impossible with traditional fabrics.

The key distinction between 2D and 3D fabrics is the addition of height and depth. In simple terms, 3D fabrics go beyond the usual flat surfaces we’re accustomed to and introduce shapes and textures that engage the senses in new ways. From clothing to interior design, the applications of 3D fabrics are vast, making them a truly groundbreaking innovation in the textile world.

The Technology Behind 3D Fabrics

3D fabric technology has evolved significantly in recent years, thanks to advances in both digital design and manufacturing processes. Designers now have access to powerful tools, such as 3D design software and 3D printers, that allow them to create highly detailed and customized textiles.

1. 3D Weaving and Knitting:

Weaving and knitting are two of the most traditional methods used to create fabrics, and they have been adapted to produce 3D textiles. In 3D weaving, multiple layers of threads are interwoven in such a way that they create a three-dimensional structure. Similarly, 3D knitting involves the use of specialized machines to knit layers of yarn into complex patterns, creating a fabric that has built-in depth and texture.

2. Additive Manufacturing (3D Printing):

3D printing is another exciting method for creating 3D fabrics. Using computer-aided design (CAD) software, designers can create digital models of the fabric, which are then printed using specialized 3D printers. These printers work by layering material, such as polymers or other textiles, to build up the fabric layer by layer. The result is a highly customizable and intricate design that would be difficult, if not impossible, to achieve with traditional fabric production methods.

3. Digital Fabric Simulation:

Advancements in digital design tools have also played a significant role in the development of 3D fabrics. Software programs like CLO 3D and Marvelous Designer allow designers to simulate fabrics in a virtual environment, creating realistic 3D models before any physical production begins. This digital approach not only reduces the need for physical prototypes, saving both time and resources, but it also opens up new possibilities for experimenting with texture, color, and form.

Applications of 3D Fabrics in Fashion

The fashion industry has been one of the first to embrace 3D fabrics, using them to push the boundaries of design, functionality, and aesthetics. Let’s look at some of the ways 3D fabrics are being used in the world of fashion today.

1. High-Fashion and Couture:

3D fabrics are becoming a mainstay in high-fashion collections, where designers are always looking for ways to stand out and offer something new. 3D fabrics allow for innovative shapes, textures, and structures that traditional textiles simply can’t replicate. Designers such as Iris van Herpen have pioneered the use of 3D-printed fabrics in their couture collections, creating avant-garde garments that look like they belong in a science fiction movie. These designs often feature sculptural elements, with textures that shift and change as the garment moves, giving the wearer a dynamic and visually stunning look.

2. Activewear and Sports Fashion:

The potential for 3D fabrics to revolutionize sportswear is immense. Because these fabrics can be designed to be lightweight, flexible, and breathable, they are perfect for performance-oriented clothing. Brands like Adidas and Nike have already started incorporating 3D textiles into their activewear lines, enhancing comfort and durability. 3D fabrics can also be used to create fabrics with built-in support or compression, making them ideal for athletes who need clothing that helps with muscle recovery or performance.

3. Sustainable Fashion:

Sustainability is an increasingly important focus in the fashion industry, and 3D fabrics are playing a role in this movement. Traditional fabric production can be resource-intensive, leading to waste and environmental concerns. By using 3D design and manufacturing techniques, designers can create textiles with minimal waste, as the process allows for more precise material usage. Additionally, 3D fabrics can be made from recycled or sustainable materials, further reducing their environmental footprint. This approach not only benefits the planet but also offers a new way for designers to think about how they source and produce their fabrics.

4. Customization and Personalization:

One of the most exciting aspects of 3D fabrics is their potential for customization. With the rise of 3D printing and digital design tools, consumers can now personalize their garments in ways that were previously unimaginable. Whether it’s creating custom textures, shapes, or sizes, 3D fabrics allow for highly individualized fashion that reflects personal style and taste. This level of customization is particularly appealing in the age of fast fashion, as it offers a more sustainable and personal approach to clothing production.

The Future of Digital Fabrics

The future of 3D fabrics looks incredibly promising, with new technological advancements and creative possibilities emerging every day. Here are a few ways 3D fabrics could shape the fashion industry in the coming years:

1. Integration with Smart Technology:

As technology continues to evolve, we may see 3D fabrics being integrated with smart technology, creating garments that respond to the environment or the wearer’s body. For example, 3D fabrics could be used in clothing that changes shape or color in response to temperature, light, or movement. This could lead to the creation of adaptive clothing that offers both functionality and aesthetic appeal.

2. Widespread Adoption in Ready-to-Wear:

While 3D fabrics have mostly been associated with high-fashion and couture collections, there’s a growing interest in incorporating them into ready-to-wear collections. As the technology becomes more accessible and affordable, we may see 3D fabrics becoming a regular part of everyday clothing lines, from casual wear to workwear and even outerwear.

3. Enhanced Sustainability:

As the fashion industry faces increasing pressure to reduce its environmental impact, 3D fabrics offer a promising solution. By using more efficient production methods, reducing waste, and incorporating sustainable materials, 3D fabrics can help brands achieve their sustainability goals. The use of 3D printing, in particular, allows for precise material usage, making it a more sustainable alternative to traditional manufacturing methods.

Conclusion

3D fabrics are reshaping the world of fashion and design, offering exciting new possibilities for creativity, functionality, and sustainability. From high-fashion couture to activewear and sustainable fashion, these textiles are opening up new avenues for designers to explore. With continued technological advancements and greater adoption of 3D printing and digital design tools, 3D fabrics are poised to play an even more significant role in the fashion industry in the future. Whether you’re a designer, a fashion enthusiast, or someone simply curious about the future of clothing, 3D fabrics are definitely something to watch.